Analysis of Non-sway type portal frame by Kani's Method (Rotation Contribution Method)

Friday, 18 June 2021

Analysis of Non-Sway type Portal Frame by Kani's Method (Rotation Contribution Method)

Thursday, 17 June 2021

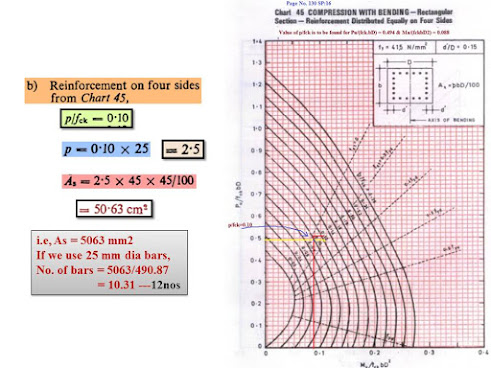

RCC Columns Subjected to uniaxial bending along with axial loading (Steel Calculation by SP16)

Subject: Structural Engineering-II (RCC) / DOS-II(RCC)

Module 05: Analysis & Design of Column

Topic:- Columns Subjected to Combined axially loaded along with uniaxial bending

Wednesday, 16 June 2021

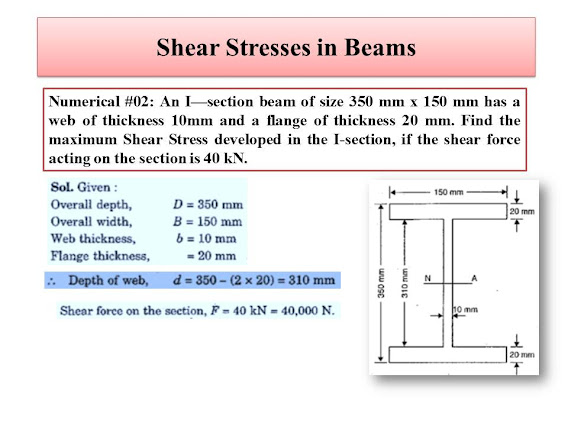

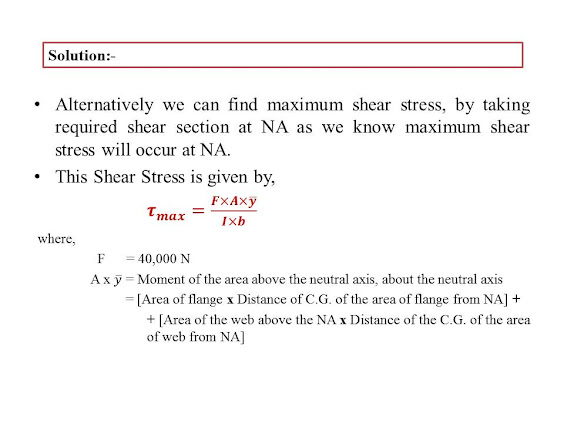

Simple Numerical on Shear Stresses in Beams Part-II (SOM)

Numerical #02: An I—section beam of size 350 mm x 150 mm has a web of thickness 10mm and a flange of thickness 20 mm. Find the maximum Shear Stress developed in the I-section, if the shear force acting on the section is 40 kN.

Simple Numerical on Shear Stresses in Beams Part-I (SOM)

Tuesday, 15 June 2021

Introduction to Concrete Technology Part-II (Cement)

Introduction to Concrete Technology Part-II (Cement)

By Md. Yousuf Shaikh Ameer

Assistant Professor

Hydration

of cement

· When Portland

cement is mixed with water its chemical compounds

undergoes a series of different chemical

reactions that cause it to harden. This chemical reaction with water is called "hydration". Every reaction

occurs at a different time and rate. Together, the results of these reactions

show how Portland

cement hardens and gains strength.

OPC hydration

Hydration starts as soon as the cement and water are added and mixed.

·

The rate of heat of hydration and the heat emmitted by the

reaction of each compound is different

·

Each compound goes

under different reactions and produces different products when it hydrates.

·

Tri-calcium silicate (C3S). Hydrates and

hardens rapidly and is wholly responsible for

initial set and early strength of cement. Portland cements with higher

percentages of C3S will gain high early strength.

·

Tri-calcium-aluminate ( C3A). Hydrates and

hardens the quickest. Liberates a large amount of heat almost

immediately after mixing and contributes somewhat

to early strength. Gypsum is added to Portland cement to

retard the amount of C3A hydration.

Without gypsum, due to C3A

Hydration it causes Portland

cement to set as quickly after adding water.

·

Di-calcium silicate (C2S). Hydrates and

hardens slowly and is mainly responsible for

strength increases beyond one week.

·

Tetra-calcium-alumino-ferrite (C4AF).

Hydrates rapidly but contributes very little to strength. By using it allows

lower kiln temperatures in Portland

cement manufacturing. Most of the Portland

cement color effects

are due to C4AF.

Heat of Hydration

·

The heat of hydration is the heat evolved when water and Portland cement react.

Heat of hydration is mostly influenced by the proportion of C3S and

C3A in the cement but is also influenced by water-cement ratio,

fineness and curing

temperature. As any one

of these factors

is increased, heat of hydration increases.

·

For usual range of Portland cements, about one-half of

the total heat is emmited between 1

and 3 days, about three-quarters in 7 days, and nearly 90 percent in 6 months.

·

The heat of hydration of

cement depends on the chemical composition of cement.

Physical

Properties of OPC and their tests

·

Portland cements are commonly checked by their

physical properties for quality control purposes. Its physical properties can be used to classify

and compare Portland cements. Now

the challenge in physical property characterization is to develop physical tests that can satisfactorily characterize key parameters.

The physical

properties of cement

·

Setting Time

·

Soundness

·

Fineness

·

Strength

Fineness:

· Fineness of

cement mostly refers to the size of grains or particles of cement. Lesser the

grain size, finer the cement. Due

to small grain size, more surface area is available for contact with water and hence the

reaction of hydration

becomes very faster, gaining of strength

is more rapid and rate of evolution of heat increases.

Test for Fineness

There are two methods prescribed in IS code for testing of fineness.

I)

Sieve Test (IS 4031, part 1 1996):

II)

Air permeability Method (IS 4031, part 2 1999)

Sieve Test (IS 4031, part 1 1996):

This is very simple test. The procedure

is given below

· Weight 100 gram of cements correctly and takes it on a standard IS sieving number 9, i.e. a sieve size 90 microns.

· Break down if any air set lumps found in the sample with fingers.

· Continuously sieve the sample giving circular and vertical motion for a period of period at least 5 minutes. Mechanical sieving device may also be used.

· Weigh the residue left on the sieve.

·

This residue shall not exceeds by the limits given as per IS CODE below

· OPC 10 gm

Rapid Hardening Cement 5gm

Air permeability Method (IS 4031, part 2 1999)

· In this method, the permeability of a cement bed for passage of air current is released with the specific surface of the grains of cement.

· The finer the grains, the more the specific surface.

· Lea and nurse permeability apparatus is used for the test, which is shown in below

fig. the diameter

of permeability cell is 2.5 cm.

·

knowing the density

of cement the weight of cement required

to make a cement bed of 0.47 porosity can be calculated. The procedure of the

test is given below.

· Fill the weight of cement as calculated above for making a bed of 0.475 porosity into the permeability cell.

· Slowly slowly pass dry air through the cement bed at a constant velocity

· Read the difference in manometer limbs and note it h1

· Read the difference in flow meter limbs and not it has h2. It should be between 30 to 50 cm.

· Repeat the readings untill steady state is achieved.

· Specific surface is calculated by following formula

K = √Ɛ3A/CL

Where Ɛ = Porosity

=0.475

L = length of cement bed (cm)

D = density

of cement in gm/cm3 C =

flow meter constant.

A =

Area of c/s of cement

bed (cm2)

Generally value of C and K

are provided be the manufacturer for different

value of porosity.

·

This specific surface

should not be less than the limits

given below. OPC:

Not less than 2250 cm2/gram

Rapid hardening cement: Not less than 3250 cm2/gram Low heat Cement: Not less than

3200 cm2/gram.

Setting Time:

Cement paste setting time is influenced by a number

of factors including:

·

Cement fineness, water-cement ratio, chemical content

(specially gypsum content) , type of cement and

admixtures. Setting tests are used to determine how a particular cement paste sets.

·

For construction purposes, the initial setting time

must not be too soon and the final settting time must not be too late.

Normally, two setting times are define:

1) Initial setting: Occurs when the paste begins to stiffen considerably and when cement will lose its plasticity.

2) Final stetting: Occurs when the cement has hardened to the point at which it can sustain some load.

Assignment on Design of Steel Structures

Module -I (Introduction & Connections) 1. Write down the advantages and disadvantages of Steel as Construction Material? 2. Which are ...

-

Subject: Structural Analysis-I (SA-I)/ TOS/ Structural Mechanics 1. If load is acting on the longitudinal axis of column, it ...

-

Subject:- SA-I-CGPA Revised (Unit I Slope & Deflection) / SOM-CGPA (Unit VI Deflection of Beams) 1. Deflection Equations method was de...

-

MCQs on Analysis of Continuous Beams (SA-I Module IV) 1 In continuous ABC, span AB of 4 m loaded with central point load ...